Work with us

Careers

Our values

As a leading global technology company, we are always looking for talents that can help us bring the latest innovative solutions to life.

Customer

Our expertise is at our customers’ disposal as we listen to their needs and develop ad hoc solutions to help them overcome challenges and achieve their objectives.

Innovation

We continually invest in research and development to develop solutions that are both innovative and effective, helping optimize the cost of the product.

Integrity

We are resolute in our commitment to act honestly, justly and with respect for our colleagues, our customers and the wider community.

People

People are the key to our success, and we work to encourage their personal and professional growth through continuous training to expand their technical and managerial skills.

Quality

We invest without compromise in innovative technology that allows us to ensure the highest quality standards and make our solutions effective and high performing.

Speed

The speed with which we execute our operations is uncommon in our sector and ensures the utmost respect for our customers’ project timetables.

Why work with us?

Because we believe in the value of people, respect their uniqueness, and appreciate the active contributions that each individual can make to the growth of a dynamic, international organization like ours. The ideas, values and efforts of the individual are dedicated to a common objective, for our success and that of our customers. Our activities are carried out with respect for the environment and for the communities where we operate.

Autonomy and responsibility

We are a lean organization that believes in a “policy of taking action”. With us, you will find active and motivating roles that will help you better advance on your professional journey.

Continuous training

Besides technological know-how, the main key to our success is the people who bring UTIL to life. We therefore promote the growth of our talented individuals through specific training, with dedicated leadership courses that foster both technical and managerial skills.

Internationalism

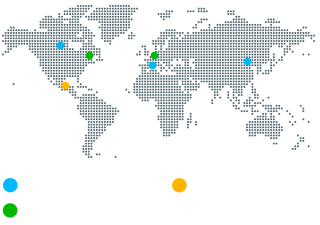

We are a global group with a strong local presence in six nations and three continents. By working with us you will be able to encounter and gain the most from the many multicultural settings that form the foundation of our international mindset.

ITALIA

Headquarters

Innovazione e tecnologia d’avanguardia a livello Globale.

GLOBAL FOOTPRINT

Sedi