Automotive

Components for brake systems

Plates and shoes for original equipment and as spare parts

Plates and shoes are fundamental components of a vehicle’s braking system. Over the years, we have consolidated our position in this sector in Europe, Asia and North America, and, thanks to our centers in Italy, Canada, China and Mexico, we are set to keep developing our business with specialized technology and manufacturing capacity.

Parts for combustion engines

Precision blanked flanges that adapt to complex pipe routes are obtained by means of Fine Blanking, which guarantees the high precision of the bolt holes and elevated repeatability of the shape obtained.

Exhaust system flanges

Stainless steel flanges that guarantee the reliability of the vehicle throughout its service life. The precise shape and positioning of the holes is essential to ensuring a perfect match with the pipes and with the components that hold the exhaust system in place.

Flanges for the cooling and lubrication systems

The precise shape and accurate and repeatable positioning of the holes are crucial to ensuring alignment with the pipes of the lubrication and cooling systems as well as with the elements used to hold the systems in place. Fine blanking technology applied to stainless steel is crucial for modern thermal management systems: for ICE, PHEV, and BEV.

Flanges for the EGR circuit

Precise shape, planarity and positioning of the holes are crucial to ensuring a perfect match with the pipes and the components that hold the EGR system in place. Stainless steel is used to resist high temperatures and corrosive agents.

Mechanical tone wheels

Mechanical tone wheels make advanced engine control strategies possible. Fine blanking technology allows for elevated repeatability when manufacturing the teeth of the tone wheel, helping generate stable engine velocity signals for both the camshaft and driveshaft. The reliable velocity sensing hardware helps optimize engine control strategies and achieve objectives in terms of emissions and fuel savings.

Turbocharger control levers

The actuator lever is an essential component of the turbocharger management system. The precise and repeatable shape of the part and strict tolerances are needed, for example, to enable the actuation of the waste gate valve in accordance with complex internal combustion engine management strategies.

Components for transmission

Gearshifts

Fine blanking allows the manufacturing of particularly precise gearshifts in terms of size, making them suitable for modern applications in manual, semiautomatic and automatic gearboxes.

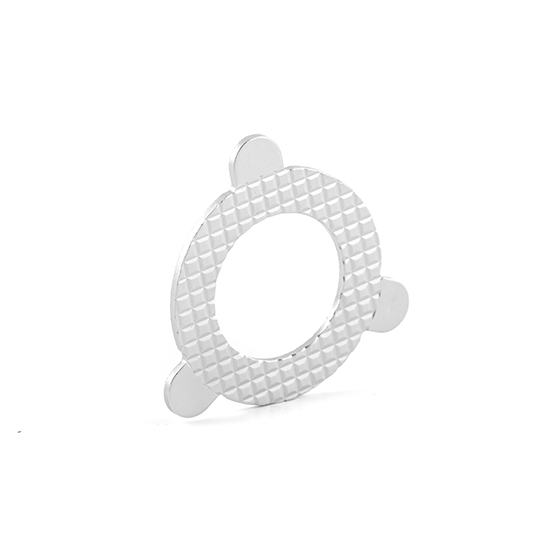

Discs for multi-disc clutches

Our clutch discs are the ideal solution for modern automatic and hybrid transmission technology. The planarity of the part and its precise shape are essential for easy assembly and for guaranteeing ultimate functionality within multi-disc clutch systems.

Parking lock system

The lever and locking wheel for parking the vehicle are essential safety components of the vehicle’s transmission system. The elevated thickness of the parts and the precise profile ensure a safe and repeatable lock, meeting the need for functionality throughout the vehicle’s life cycle.

Metal gaskets

The complex shape and the multiple perforation schemes, with controlled shapes and positions, enable the proper functioning of the hydraulic system that uses the component. The planarity and roughness of the aluminum support are controlled and the proper shape of the holes is guaranteed thanks to the use of fine blanking technology.

Parts for interiors and vehicle locking systems

Levers for the latches and for locking the doors

Levers for door and hatch openers featuring complex and precise shapes that ensure proper pairing with the vehicle’s locking systems. The surfaces can be manufactured with the roughness needed for co-stamping with plastic materials, for example.

Toothed segments for seat adjustment

Adjustment racks are an essential component for passenger comfort. Fine blanking technology contributes to the precise, affordable and repeatable manufacture of toothed racks and support levers in a single piece, even where complex shapes and features are needed.

Applications

Headquarters

Sedi