Cutting-edge solutions for high-precision mechanics

We design and engineer technological solutions for the production of high quality parts used in various industrial sectors, from the automotive sector to agricultural and earth-moving machines, construction and e-mobility.

Ours is one of the few vertically integratedcompanies in the sector, and we manage the design and construction of the toolings internally. We are therefore able to provide a complete service from the prototyping of a few samples all the way to the manufacturing of large batches. This allows our customers to evaluate the product carefully and make informed decisions before initiating the production of large batches.

Fine blanking

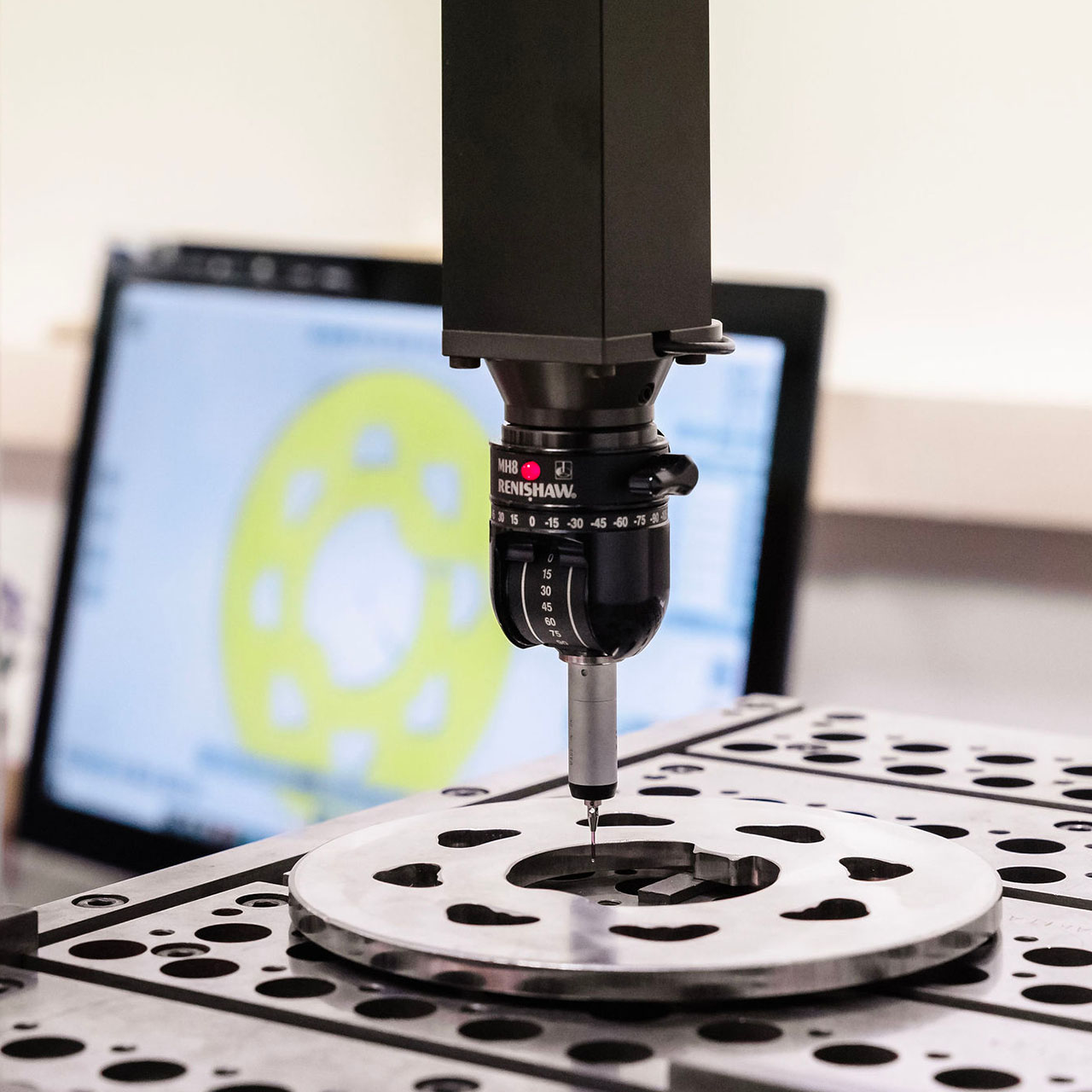

Fine blanking is our flagship technology and our customers recognize our reliability in providing high quality finished products in terms of rigorous compliance with design tolerances – down to a hundredth of a millimeter – and an accurate surface finish.

Fine blanking technology allows us to manufacture high-precision components with a “net shape” in large quantities with a repeatable process, minimizing waste, reducing costs and the time required for machining with presses that operate within the range of 630 to 1,400 tons.

Conventional blanking

Conventional blanking guarantees good repeatability of the manufacturing process even for batches of millions of pieces with reduced development and equipment costs compared to fine blanking.

Therefore, this technology is best suited for applications in which the price/quality ratio for the finished product is of primary importance but with less stringent tolerances. Presses for conventional blanking typically operate within an interval of 700 to 800 tons.

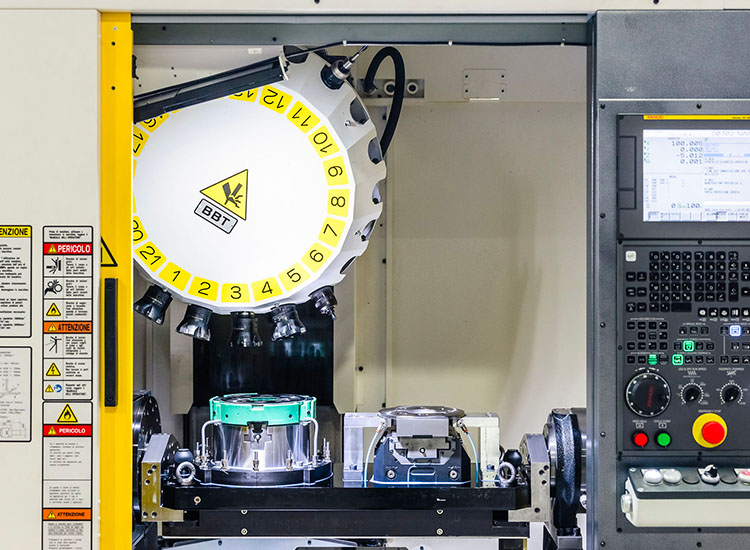

Secondary operations

Thanks to our extensive expertise in mechanical technology, here at Util we are able to carry out the main secondary machining steps to increase the quality and flatness of products manufactured using blanking, such as: CNC machining, grinding, milling, brushing, thermal surface treatments, threading, coating, insertion of screws.

High quality steel and aluminum alloys

- Carbon steel • 1.0332 • 1.0330 • 1.0038 • 1.0044 • 1.0976 • 1.0980 • 1.0984 • 1.0986 • 1.0511 • 1.0503 • 1.7131

- Stainless steel • 1.4301 • 1.4306 • 1.4307 • 1.4512 • 1.4509 • 1.4510

- Aluminum alloys • 5182 • 5083 • 6062 • 6061

Sustainability and advanced materials

Thanks to our research center in Italy, as UTIL we invest considerable effort in designing and engineering cutting-edge solutions that also aim to limit environmental impact in terms of energy consumption and raw materials.

In addition, we work to extend our expertise in innovative materials such as next generation steel and copper alloys.

We believe in the value of teamwork, which is why we cooperate with leading partners for the joint development of next generation equipment and have embarked on research projects with the best Italian universities for the development of digital applications.

News from the world of Util

UTIL is pleased to announce the new partnership for the development, growth and consolidation of the production base of Util Industries S.p.A.

The 3-year research and development program focuses on the design of

The ability to learn and develop oneself further is by far the most important quality a professional

Send us a message

Headquarters

Sedi